In that case, you will need to add two setpoints into that list: Layer 1 at 0% fan speed, and Layer 5 at 100% fan speed.

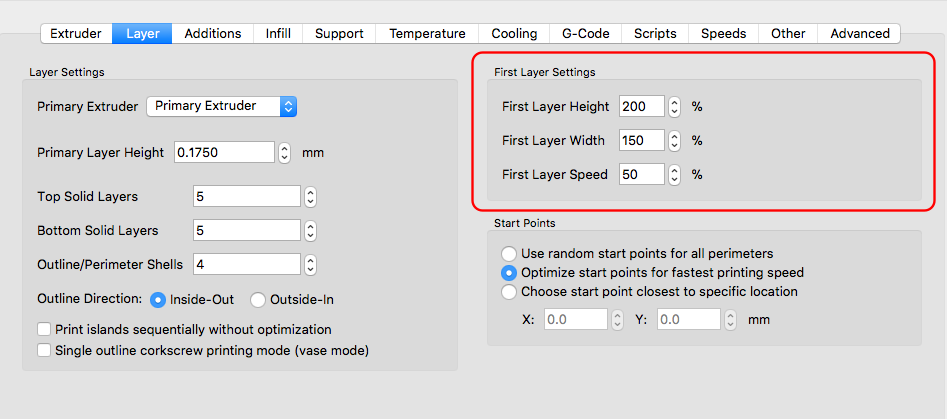

SIMPLIFY 3D FIRST LAYER HEIGHT FULL

For example, you may want the first layer to start with the fan disabled and then turn on the fan to full power once you reach the 5th layer. You can adjust the fan speed setpoints on the left-hand side. You can do this by clicking “Edit Process Settings” and going to the Cooling tab. If your printer has a cooling fan, you may also want to try disabling that cooling fan for the first few layers of your printer so that the initial layers do not cool down too quickly. You can just double-click on the value to change it. Choose your heated build platform from the list on the left-hand side and then edit the temperature setpoint for the first layer. You can adjust these settings in Simplif圓D by clicking on “Edit Process Settings” and then selecting the Temperature tab. As a general starting point, PLA tends to adhere well to a bed that is heated to 60-70C, while ABS generally works better if the bed is heated to 100-120C. So if your printer has a heated bed, you may want to try heating the bed to prevent the first layer from cooling. If the bed is heated to maintain a temperature of 110C for the entire print, it will keep the first layer warm so that it does not shrink. Many printers that are intended to print high-temperature materials like ABS include a heated bed to help combat these problems. If you notice that the layer seems to stick initially, but later separates from the print bed as it cools, it is possible that your temperature and cooling settings are to blame. This is an important fact to keep in mind as you print your first layer. Because of this fact, the plastic will tend to separate from the build platform as it cools. If this ABS part cooled down to a room temperature of 30C, the 100mm wide part would shrink by almost 1.5mm! Unfortunately, the build platform on your printer is not going to shrink this much, since it is typically kept at a fairly constant temperature. Some printers also include cooling fans that speed up this cooling process when they are being used.

If the extruder was printing this plastic at 230 degrees Celsius, but it was being deposited onto a cold build platform, it is likely that the plastic would quickly cool down after leaving the hot nozzle. To provide a useful example, imagine a 100mm wide part that is being printed with ABS plastic. Plastic tends to shrink as it cools from a warm temperature to a cool temperature. Each layer of your part is usually only around 0.2mm thick, so a small adjustment goes a long way! Be careful to only make small adjustments to this setting. For example, if you enter -0.05mm for the Z-axis G-Code offset, the nozzle will begin printing 0.05mm closer to your build platform. You can use the Z-Axis global G-Code Offset to make very fine adjustments to your nozzle position. To do this, click “Edit Process Settings” to open your process settings and then go to the G-Code tab. While you can adjust these settings by modifying the hardware, it is typically much easier (and much more precise!) to make these changes from Simplif圓D. For good adhesion to the build plate, you want your filament to be slightly squished against the build plate. Your goal is to locate your extruder the perfect distance away from the build plate - not too far and not too close. Once your bed has been properly leveled, you still need to make sure that the nozzle is starting at the correct height relative to the build platform.

0 kommentar(er)

0 kommentar(er)